Optician2020 project builds on the outcomes of the European project Made4U (www.made4U.info), carried out by 13 European partners and successfully concluded in July 2012. In this project, several business models were investigated, in parallel to the development of scanning, design and manufacturing technologies suitable for personalised polymeric spectacles production, up to a pre-competitive stage.

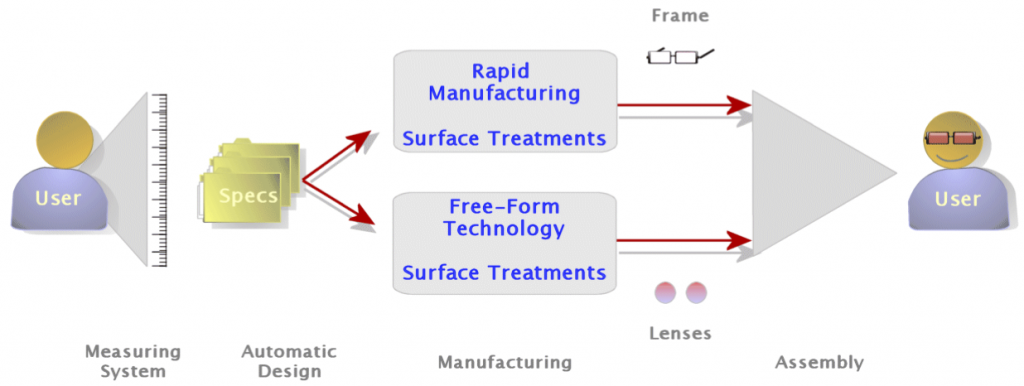

Fig. Schematics of the process developed in concluded Made4U project.

There are no proven technologies and methods that achieve a high degree of personalization of spectacles. Made4U solution spanned over the entire value-chain, also including the end-users themselves.

Based on face and head morphology measurements, together with lens prescription data, the target pair of spectacles was automatically designed in 3D-CAD. The precise lens, frame surface treatments and decoration were selected by end-users.

During the four years of the project, the proposed objectives in terms of advanced technologies, proof of concept (demonstrator) and business models for a flexible and easily reconfigurable supply chain with multiple contributors were achieved. It was also demonstrated a new user co-design buying experience that could lead place personalization of products at the forefront of added-value commercial offerings.

In summary, the main innovative results of Made4U project were:

- An innovative user data-capture device provides the user morphological information required to personalize a frame. Two final prototypes were constructed and intensively tested during the demonstration stage. The accuracy of the data provided by the scanning device is precise enough for the purpose of the virtual lens fitting.

- A catalogue of nine 3D personalized frames was available for the first time with the capability to be modified within a wide range of dimensions, making the personalization available to a large number of possible users.

- A prototype for coating ophthalmic lenses was able to apply good quality uniform tints. A set of mirrors and anti-reflective coatings of different colors is available with recipes that provide good quality coatings.

- Polyamide and Titanium frames can be produced by laser sintering for the first time. Laser-sintering processes and materials were optimized.

- 3 innovative Business Models to commercialize the personalized spectacles that were tested in the demonstrator stage of Made4U.

During the last months of the project, a demonstrator of the technologies developed ran in real conditions in two opticians, scanning 160 users that participated in the co-design process of their personalized spectacles.